Big Spring Water Treatment Plant

Crab Orchard National Wildlife Refuge

St. Louis Formerly Utilized Sites Remedial Action Project (FUSRAP)

Man-Made Features Removal, Orphan Mine Site

Nuclear Disposal Area West Valley

|

| Big Spring Water Treatment Plant |

|

Click photo to enlarge |

CLIENT

Bechtel Jacobs/Department of Energy

LOCATION

Y-12 National Security Complex, Oak Ridge, TN

AMOUNT

$5.5 Million |

This project included the dismantlement and demolition of Bldgs. 9610, 999-4, and Tank 9500-004. The scope included removal and remediation of asbestos containing materials, mercury components, building debris and concrete, associated metals, and PCB’s.

Due to past operations at the U.S. Department of Energy’s Y-12 National Security Complex, releases of mercury had occurred to the environment. Pangea Inc. was contracted to construct a new 300 – gpm water treatment system to remove total mercury from groundwater discharged from Outfall 51 and groundwater collected in the basement sumps of Building 9201-2. The Big Spring Water Treatment Project was constructed by Pangea Inc. as a Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) action in accordance with the Record of Decision for Phase I Interim Source Control in the Upper East Fork Popular Creek Characterization Area, Oak Ridge, TN.

Pangea was required to perform selective demolition of existing structures at the site, characterize and dispose of debris, construct an interim collection and mercury treatment system, construct the Big Spring Water Treatment Facility including: construction of a pre-fabricated metal building to house the new treatment system, and provide system testing and startup support. The collection system was comprised of piping from an existing spring box, Building 9201-2 sumps, a wet well and an equalization tank. The treatment system consisted of two parallel trains of triplex granular activated carbon columns operated in series. The project included the submission and approval of project-specific work plans, participation in a readiness review, and mobilization. Pangea was responsible for the entire turn-key project.

back to top |

|

| Crab Orchard Site 36 |

|

Click photo to enlarge |

CLIENT

U. S. Department of the Interior, Bureau of Reclamation

LOCATION

Crab Orchard National Wildlife Refuge, Marion, IL

AMOUNT

$4.2 Million |

The Site 36-Miscellaneous Areas Operable Unit Remediation Project, involved the closure of a 21-acre Wastewater Treatment Plant (WWTP) located at the Crab Orchard National Wildlife Refuge in Marion, Illinois. The WWTP was constructed as part of the Illinois Ordnance Plant (IOP) in the 1940s and was operated continuously until recently. The site covered about 50 acres and included both recently used treatment facilities and others that had not been used for some time, plus adjacent ground and drainage channels.

For years during weapons production at the facility, upstream industrial processes produced wastes that contained PCBs and heavy metals. The remediation scope of work included the removal of all contaminated soils, sludge, and sediments, as well as the demolition and removal all WWTP lagoons and structures.

Pangea self-performed all significant work on this project. Pangea carefully planned the sequence of work necessary to complete the fieldwork in the initial four-month period. The initial scope of work included the following:

-

Removal and dewatering of sludge from the anaerobic digester, cleaning and testing the digester, and disposing of approximately 990 CY of the sludge. PCB concentrations in the sludge are > 50 milligrams per kilogram (mg/kg) (dry weight) and the sludge was disposed of in a chemical waste landfill in accordance with 40 CFR 761.

-

Removal and dewatering of approximately 350 CY of sludge from the treatment plant. The dewatered sludge had PCB concentrations < 50 mg/kg and was disposed of in an off�site landfill permitted under Subtitle D of RCRA ("Subtitle D landfill").

-

Demolition of the wastewater treatment plant and disposal of the waste concrete materials in a Subtitle D landfill.

-

On-site treatment of approximately 690,000 gallons of water to meet State of Illinois General Use Surface Water Quality Standards and discharge to a nearby stream under the facility’s NPDES permit.

-

Removal and dewatering of approximately 1750 CY of sludge from the East Pond and disposal in a chemical waste landfill.

-

Removal and dewatering of approximately 11,000 CY of sludge from the Primary and Secondary lagoons and disposal in a Subtitle D landfill.

-

Site restoration of approximately 24 acres, including re-grading, topsoil replacement, and re-establishment of vegetation.

As the project progressed, it was discovered that substantially increased volumes of PCB contaminated sediments and soils were present on the site. The final volume of contaminated sludge, sediments, and soils removed from the site totaled over 30,000 cubic yards. In addition, approximately 350 cubic yards of soil contaminated with cadmium were excavated and transported for disposal. The project performance period was extended by approximately six months to accommodate the expansion of work scope.

back to top |

|

| St. Louis Formerly Utilized Sites Remedial Action Project |

|

Click photo to enlarge |

CLIENT

U.S. Army Corps of Engineers and others

LOCATION

St. Louis, Missouri

AMOUNT

Ongoing |

The Formerly Utilized Sites Remedial Action Project (FUSRAP) is a $135 million dollar partial program in St. Louis, Missouri. Other related sites exist in New York and New Jersey. The FUSRAP program was originally a Department of Energy program designed to clean up properties and businesses contaminated during the nuclear build up beginning in the early 1950's until the late 1970's. This program was turned over to the Army in 1998 and multiple Corps Districts and management contractors now handle the work.

Pangea is providing scientific and remeidiation support through our Services Group to Shaw Environmental and Science Applications International Corp (SAIC). Pangea provides various levels of staff to assist Shaw and SAIC in their daily activities, from radiological laboratory technicians and hazardous waste shippers, to environmental health and safety representatives. Pangea’s employees perform quality control, soil and water sampling, data management, regulatory oversight and transportation and disposal coordination. All site personnel have a minimum of five years experience working on radiologically contaminated sites and have the necessary training (HAZWOPER, RCRA, RadWorker, IATA, DOT Hazmat Shipping, etc) to direct all phases of the radioactive waste management cycle.

Pangea also performed multiple construction tasks to support operations at the FUSRAP site under an Indefinite Delivery Task Order Construction Contract with Shaw. Tasks included:

• Project Management Office Building Rehabilitation

• Construction of a New Testing Laboratory

• Selective Excavation, Sewer Line Installation and Site Restoration

• Modular Building Relocation

• Site Preparation

back to top |

|

| Man-Made Features Removal, Orphan Mine Site |

|

Click photo to enlarge |

CLIENT

U. S. Department of the Interior, Bureau of Reclamation

LOCATION

Grand Canyon National Park, Arizona

AMOUNT

$2.4M |

Pangea was contracted by The Department of Interior, Bureau of Reclamation (Reclamation) to provide work and services for the removal of Man-Made Features (MFR) in the Upper Mine Area of Operable Unit 1 of the Orphan Mine Site in Grand Canyon National Park, Arizona The MFR was the first step of an EE/CA commissioned by the National Park Service for remediation and removal of an abandoned Uranium Mine on the south rim of the Grand Canyon. The removal featured the demolition of a 70-foot tall headframe structure extending over the edge of the canyon as well as the removal of several dozen radiologically contaminated structures spread over a 3-acre site. A total of 22 Man-Made Features and 5 Debris Concentration Areas were removed, making for more than 1600 tons of features removed. These Features consisted of the Head-Frame structure, mining-related equipment, buildings abandoned on site, debris both on the site footprint and over the edge of the canyon, and a small amount of non-mining related items. Other work activities under this contract included an initial site scoping evaluation, building a project specific concrete decon pad, as well as waste characterization, profiling, transportation, and disposal, of over 1000 tons of radiologically contaminated waste.

The demolition and removal of the headframe structure involved two 140 ton extended-boom cranes, a specialty rigging subcontractor to disassemble the structure without torches, rope access technicians performing removal operations over a 1600 ft vertical shaft, and installation of a steel cap for closure of the mine shaft.

Pangea’s technical climbers were able to place a 300-foot safety/debris netting across the mouth of the canyon preventing the possibility of lost material and ensuring workers near the edge had safe platform from which to perform work. Pangea employed certified wilderness climbers for this work over the rim to assure a safe project with this high-risk aspect of the project.

Wastes were screened, segregated, surveyed, and placed into waste containers in an efficient manner that minimized the ability of the unique canyon weather to interrupt the project schedule while minimizing the amount of waste requiring radiological disposal. Radiological survey data was also gathered on various members of the headframe for a dose reconstruction model of the tower, to be completed later this year. While the project yielded over 1000 tons of radiologically contaminated material, Pangea was able to employ an innovative characterization approach that allowed large cost savings through the use of an alternate disposal facility.

All work had to be completed during the winter months in order to avoid disturbing the California Condor and Spotted Owl nesting seasons.

back to top |

|

| Nuclear Disposal Area West Valley |

|

Click photo to enlarge |

CLIENT

West Valley Environmental Service

LOCATION

West Valley Nuclear Disposal Area, West Valley, NY

AMOUNT

$4.3 Million |

West Valley is a complex radioactive waste site with long-lasting nuclear waste mainly from atomic weapons and power production and some other generators. The site known as the Nuclear Disposal Area (NDA) has buried waste consisting of high-level, “low-level” transuranic and mixed (radioactive and hazardous) wastes. Burial of radioactive waste in 20-30 foot deep trenches began in the early 1960s and continued until 1974 when water filled up the trenches, burst through the trench. Another 190,000 cubic feet were disposed there from 1982 to 1986 as part of the early West Valley Demonstration Project.

To prevent the infiltration of groundwater and surface water into the NDA, Pangea was contracted to construct an 850-foot underground soil-bentonite slurry wall on two upgradient sides of the NDA and install a 410,000 ft2 geomembrane cap over the NDA. Prior to the start of construction activities, Pangea prepared the NDA and established construction boundaries with appropriate postings and barriers for the NDA project.

The construction of the groundwater barrier wall included construction of a working platform and slurry mixing pad; preparation, placement and cleaning of slurry; excavation of the slurry trench; stockpiling; sand and sediment removal from the slurry trench bottom; cobble and boulder removal; supplying, hauling, blending and placing all backfill materials; temporary and permanent treatment of the top of the slurry wall; disposal of excess slurry and quality control testing.

The construction of the geomembrane cover included installation of a Geotextile cushion for protection of the geomembrane. Pangea also fabricated and installed an XR-5 geomembrane cap and Jersey barriers.

Pangea also installed upgrades to the storm water drainage system in the vicinity of the NDA. The installation of the stormwater draining system included excavation of trenches and installation of new catch basin, storm draining pipes and related structures, including backfilling to the grade. Pangea provided all as-built dimensions and invert pipe elevations.

In addition, Pangea performed relevant ancillary work such as monitoring well abandonment and installation, soil testing, civil land surveys, clearing and grubbing, management of surface water and erosion controls, equipment decontamination, and waste characterization and transportation, and site restoration.

back to top

|

We are ready to support your next project with proven solutions.

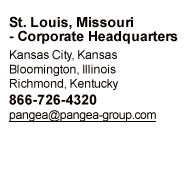

Call 314-333-0600 or pangea@pangea-group.com |

• Engineering & Surveying

• Environmental Services

• Civil Construction

• Facility Construction

We have continually expanded our areas of expertise to meet the growing needs of our clients, including the ability to address environmental controls and government regulations. We have the staff and resources in house to handle every phase of a project - from design concept to construction administration.

MICHAEL

ZAMBRANA

PRESIDENT & CEO OF PANGEA GROUP

|